Migration- and Permeation Simulations in the Headspace

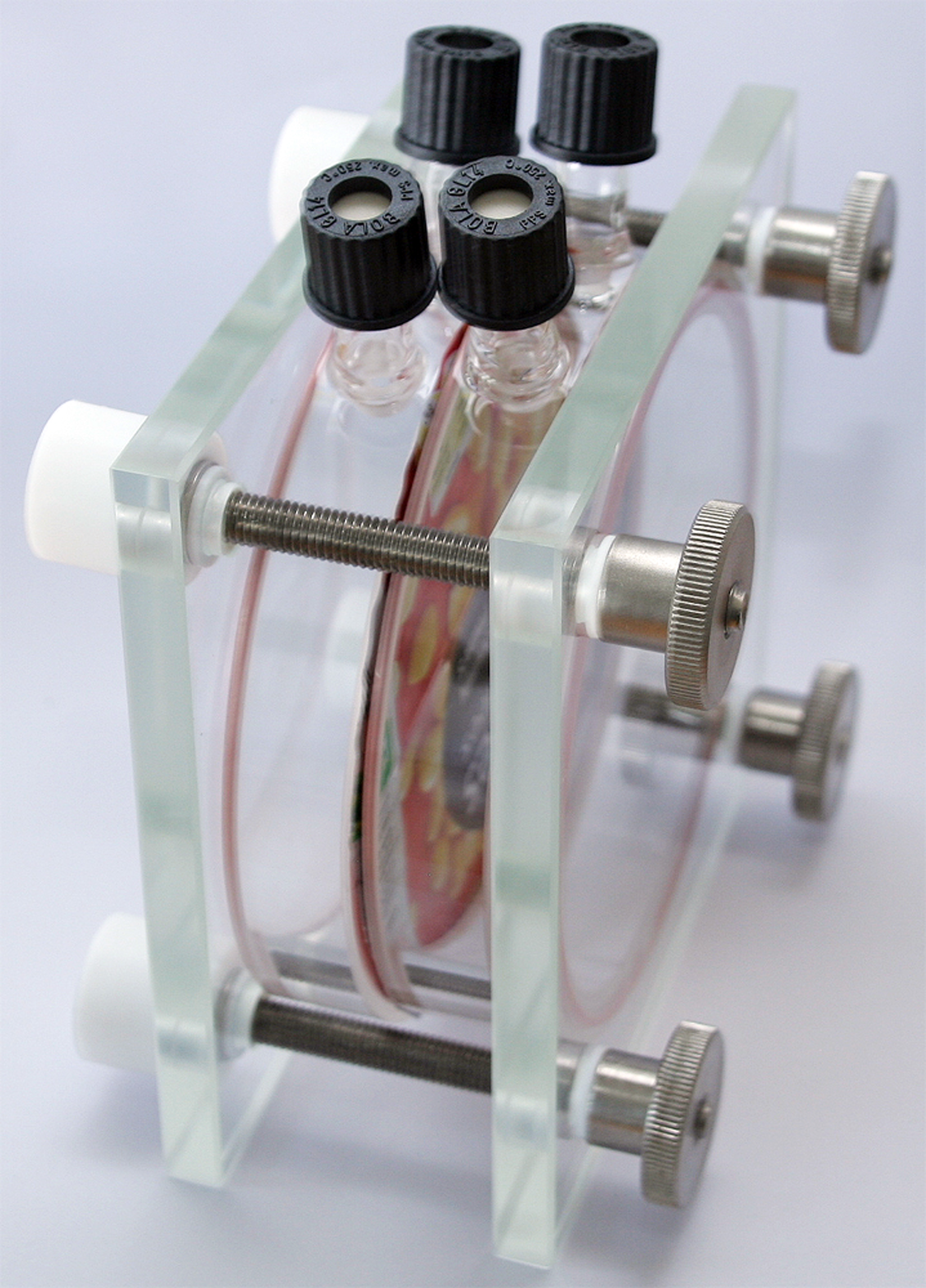

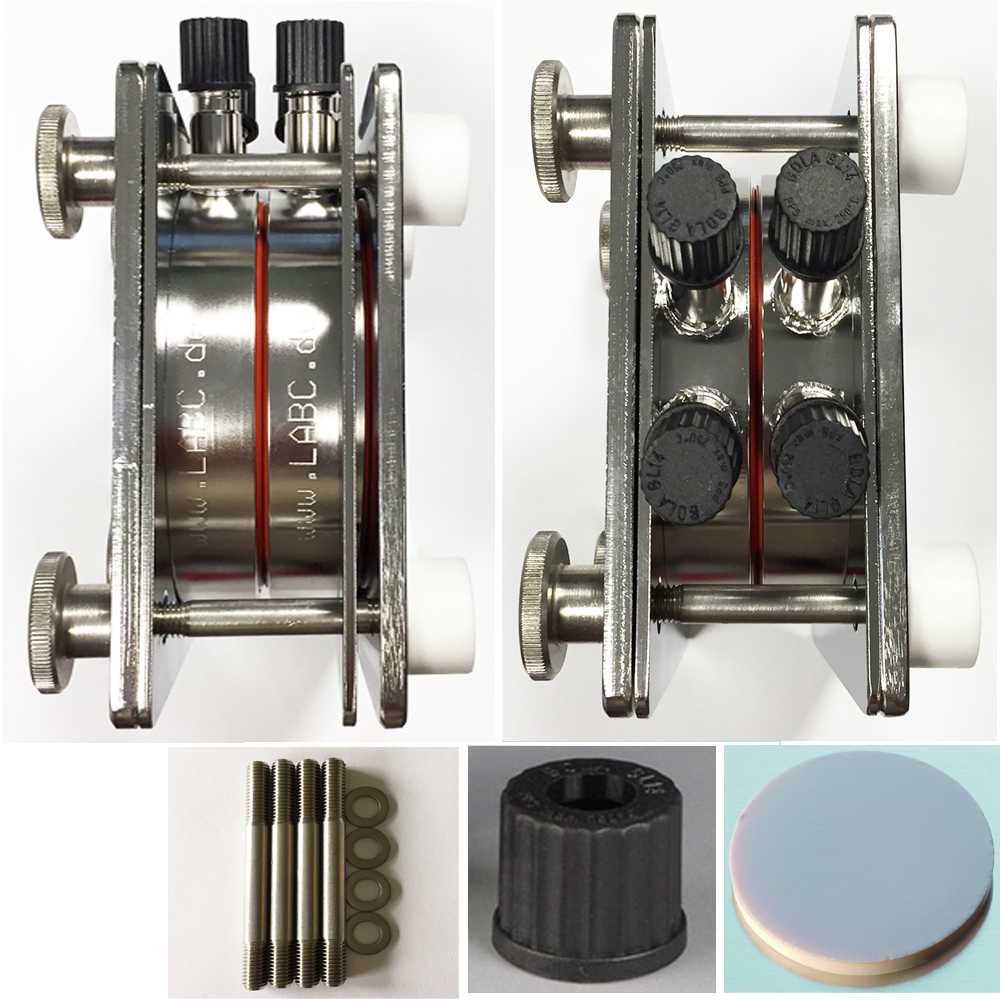

With the modular Migration Cell System-Siegwerk (Sieg-Mi-Flex) with the experimental setup: "Sandwich Set-Up".

Without the influence of cut or seal edges, simulations of migration or permeation can occur without food simulants over a wide temperature range and under pressure. The modular design and the materials stainless steel, borosilicate glass and PVDF allow many variants.

Simulation examples of mass transfers:

- Migration testing of the top and bottom of a packaging film in the headspace without the influence of food simulants

- Migration check via a free space (no direct contact with the packaging film!)

- Permeation test for permeability of shielding gases through composite packaging films

- Permeation test on the barrier effect of the plastic inner bags in cardboard boxes in the gas space (headspace)

- Gas permeability of membrane films

- Permeation test for permeability of filled epoxy plates by H2S, H2O, CO2 and O2.

„Sandwich Set-Up“ with the modular Sieg-Mi-Flex system:

Simulations, Sampling and Sample Preparation:

The migration simulation of the top and bottom of a packaging film is carried out in the headspace without the influence of food simulants as a function of time and temperature.

The test sample is clamped between the two middle rings.

Sampling and enrichment from the head rooms is done with an inert carrier gas, which flushes through the headspace and concentrates the analytes on an adsorption tube.

Alternatively via SPME (solid phase microextraction) or PowerSorb® rods.

The migration simulation of the top and bottom of a packaging film is carried out in the headspace without the influence of food simulants as a function of time and temperature.

The test sample is clamped between the two middle rings.

Sampling and enrichment from the head rooms is done with an inert carrier gas, which flushes through the headspace and concentrates the analytes on an adsorption tube.

Alternatively via SPME (solid phase microextraction) or PowerSorb® rods.- Migration simulation for checking the mass transfer, depending on time and temperature, via a free space (no direct contact with the packaging film!) from a film test piece (clamped between both center rings!) to the TENAX® or PowerSorb® rods distributed at the cell bottom.

- Checking the barrier effect (permeation reduction) of inner bags in cardboard boxes in the headspace. The carton of the carton (donor) is stretched between a fixing plate and a center ring, the inner bag foil to be tested (test pattern) is clamped between the two middle rings. The permeation simulation then takes place as a function of time and temperature. Sampling and enrichment from the gas spaces is done with an inert carrier gas, which flushes through the headspace and concentrates the analytes on an adsorption tube. Alternatively via SPME (solid phase microextraction) or PowerSorb® rods.

Testing the barrier properties (permeation) of composite packaging films under the action of modified atmospheres (keyword: Modified Atmosphere Packaging, MAP) such as (H20, CO2, N2, O2) composite packaging.

The test sample is clamped between the two middle rings.

Subsequently, the permeation simulation depending on the time and temperature.

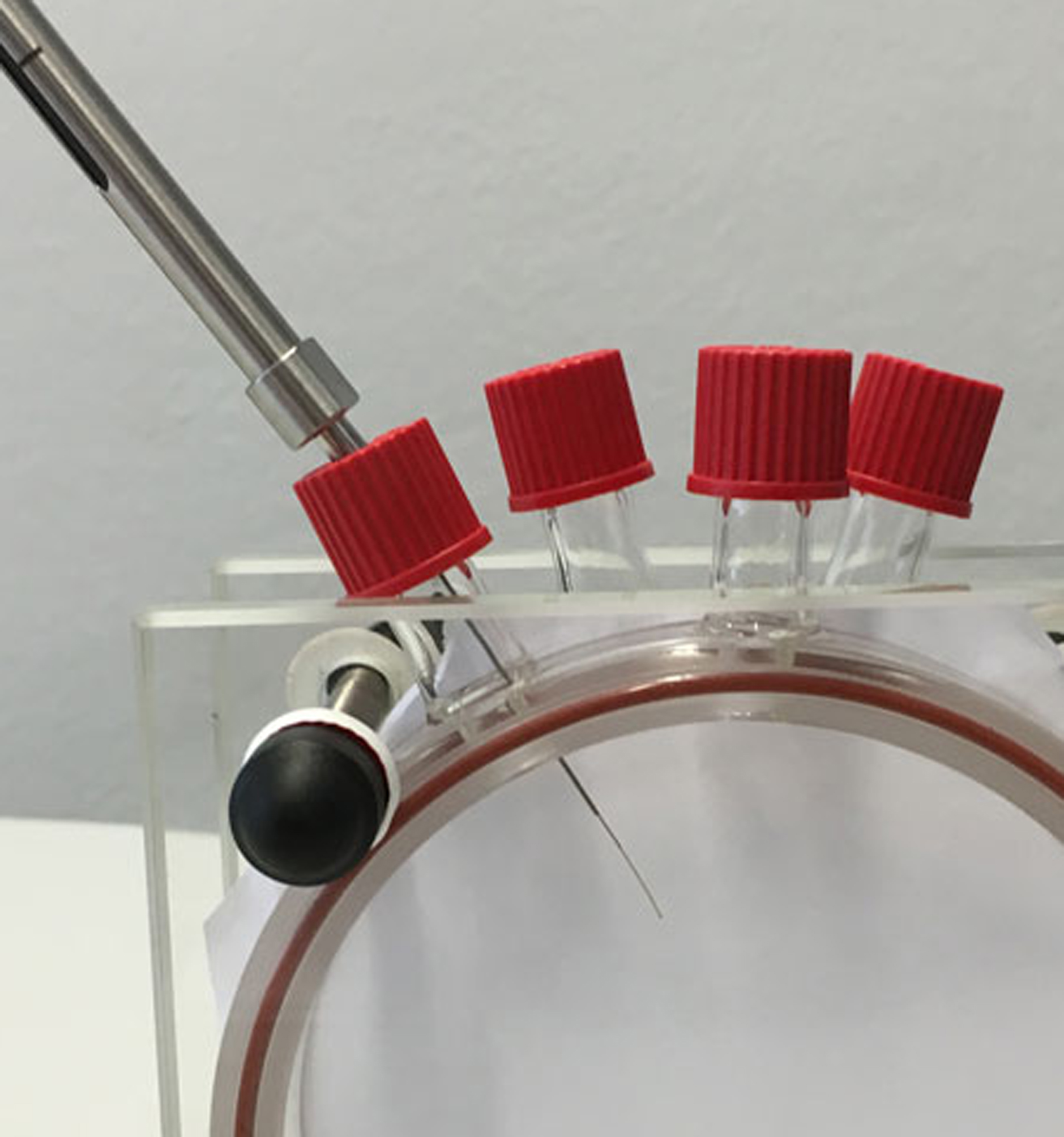

The protective gas concentration is measured without sample preparation with a gas analyzer of the MAT1000 series.

For this purpose, the suction needle of the gas analyzer is inserted through the septum of the GL14 screw cap in the headspace of the package.

Testing the barrier properties (permeation) of composite packaging films under the action of modified atmospheres (keyword: Modified Atmosphere Packaging, MAP) such as (H20, CO2, N2, O2) composite packaging.

The test sample is clamped between the two middle rings.

Subsequently, the permeation simulation depending on the time and temperature.

The protective gas concentration is measured without sample preparation with a gas analyzer of the MAT1000 series.

For this purpose, the suction needle of the gas analyzer is inserted through the septum of the GL14 screw cap in the headspace of the package.- Testing for gas permeability filled epoxy plates (1mm thick) e. g. of H2S (hydrogen sulphide), CO2 (carbon dioxide) or O2 (oxygen). The headspace can be pressureless with the test gases or with e. g. be filled with 1-3bar overpressure. CO2 (carbon dioxide) and O2 (oxygen) may e. g. as described under 4. The sampling and enrichment of H2S (hydrogen sulfide) from the opposite headspace is carried out with an inert carrier gas, which is flushed through the headspace and passed through an N ', N-dimethyl-p-phenylenediamine solution. H2S (Hydrogen sulfide reacts with N ', N-dimethyl-p-phenylenediamine to form methylene blue, using iron (III) salts as catalyst. The reaction product has an absorption maximum at 670 nanometers and can be determined photometrically (B. Lange, ZJ Vejdelek: Photometric Analysis, Verlag Chemie, Weinheim 1980, ISBN 3-527-25853-1.)

Alternatively, an ALTAIR 5X multi-gas meter with H2S sensor can be used. Again, the headspace is flushed with an inert carrier gas.

Both the test gases and the inert gases can be introduced via the 2 side sockets with GL14 thread of the middle rings or through them (without pressure or with, for example, with 1 - 3 bar overpressure).

The temperature control can be done in a bath thermostat or in drying cabinets.

In addition to the "Sandwich Set-Up" made of stainless steel or borosilicate glass, it is also possible to combine components of the Sieg-Mi-Flex System made of borosilicate glass, PVDF (only available as center ring!) and stainless steel and thus flexibly adapt to a specific task (temperature-resistant -15 ° C up to 180 ° C).

Furthermore, the middle rings are available in different diameters.